Table Of Contents

Are you interested in learning more about plastering and the tools used in this essential construction technique?

We will explore the different types of plastering, including traditional, gypsum, cement, lime, and polymer-modified plastering.

Discover the essential tools needed for plastering such as trowels, hawks, darbies, and more, along with optional tools that can make your plastering project easier!

What Is Plastering?

Plastering is a skilled craft that involves applying a smooth, durable finish to walls and ceilings using materials such as plaster and tools like trowels and floats.

Plastering is an ancient art that dates back to civilizations like ancient Egypt and Greece, where it was used not only for aesthetic purposes but also for practical reasons.

One of the primary purposes of plastering

is to protect walls and ceilings from moisture damage, cracks, and other wear and tear. It provides a smooth surface for painting or wallpapering and contributes to the overall aesthetic appeal of a space. Various techniques such as skim coating, floating, and stucco application are employed in the plastering process, each serving a specific purpose in achieving the desired finish. Plastering plays a significant role in the construction industry, ensuring the structural integrity and visual appeal of buildings.

Gain insights: Can You Paint New Plaster

What Are The Different Types Of Plastering?

There are several types of plastering methods, including traditional, gypsum, cement, lime, and polymer-modified plastering, each with unique characteristics and applications.

Traditional plastering, also known as mud plastering, is the oldest form of plastering dating back to ancient civilizations. It involves using a mixture of clay, sand, and straw that is applied to the walls in layers. This type of plastering is known for its durability but requires skill and experience to apply correctly.

Gypsum plastering, on the other hand, is a modern method that uses gypsum powder and water to create a smooth finish. It is commonly used in indoor spaces due to its quick drying time and fire-resistant properties.

Traditional Plastering

Traditional plastering is a time-honored technique used for creating smooth and durable surfaces on walls and ceilings, often involving hand tools like hammers and spackle knives.

This method typically begins with applying a base coat of lime plaster to the surface, followed by a finish coat for a polished appearance. The materials used in traditional plastering often include sand, water, and lime, which are mixed to the desired consistency. This process allows for intricate detailing and custom designs to be added to the surface, enhancing the overall aesthetic of the space. Common applications of traditional plastering can be seen in historical buildings, churches, and traditional homes where the craftsmanship and durability of plaster are highly valued.

Gypsum Plastering

Gypsum plastering is a popular method that utilizes gypsum-based materials mixed with water to create a smooth finish, requiring tools like buckets, utility knives, and paddle mixers for application.

Once the gypsum plaster mix is prepared, it is applied to walls, ceilings, and other surfaces to provide a durable and aesthetic coating. The material sets quickly, making it a time-efficient option for projects. Plus its quick setting time, gypsum plaster offers excellent fire resistance, sound insulation, and moisture control properties, making it ideal for use in buildings where these features are essential. Interior spaces such as homes, offices, and commercial establishments benefit greatly from the versatility and quality finish that gypsum plastering provides.

Cement Plastering

Cement plastering involves the application of a cement-based mix to create a strong, durable surface, utilizing tools like bucket trowels, hawks, and traditional trowels for precise finishing.

One of the key advantages of using cement plaster is its high durability and strength, making it an ideal choice for both interior and exterior surfaces. The process begins with preparing the surface by cleaning it thoroughly and applying a bonding agent to ensure proper adhesion.

Once the surface is ready, the cement mix is prepared by mixing cement, sand, and water in the correct ratios to achieve the desired consistency. The mix is then applied using a hawk and trowel, with skilled workers ensuring an even and smooth finish.

Efficiency is crucial in cement plastering, and using the right tools such as corner trowels, float blades, and darbies can significantly improve the application process, resulting in a professional-looking finish.

Lime Plastering

Lime plastering involves the use of lime-based materials to create a breathable and flexible finish, often requiring specialized tools like window trowels, corner trowels, and mortar stands.

One of the key characteristics of lime plastering is its ability to regulate moisture levels within a building, preventing issues such as dampness and mold growth.

The use of lime plaster is a preferred choice for historic buildings due to its compatibility with traditional construction methods and its natural aesthetic appeal that enhances the authenticity of the structure.

Tools like window trowels and corner trowels play a crucial role in achieving a smooth and uniform finish on curved surfaces and corners, ensuring precision in the application of lime plaster.

Polymer Modified Plastering

Polymer-modified plastering involves the use of polymer-enhanced materials for increased strength and flexibility, often requiring tools like sponge/sandpaper, plasterers' floats, jointing knives, and scarifiers for optimal application.

One of the key advantages of using polymer-modified plastering techniques is the ability to create a more durable and resilient finish compared to traditional methods. The polymer additives improve adhesion, reduce cracking, and enhance overall performance over time, making the plaster more resistant to weathering and wear. This results in a longer-lasting and low-maintenance surface, ideal for both indoor and outdoor applications.

What Are The Essential Tools Used In Plastering?

The essential tools used in plastering include trowels, hawks, darbies, floats, jointing knives, brushes, buckets, mixing paddles, machines, and levels, each serving a specific purpose in the plastering process.

Trowels, for instance, are used for applying and smoothing plaster onto surfaces with precision, while hawks provide a convenient platform for holding the plaster mixture. Darbies are essential for achieving a straight and smooth finish, ensuring an even distribution of plaster. Floats, on the other hand, help in compacting and smoothing the plaster surface, creating an even texture. Jointing knives aid in shaping and detailing corners and edges, enhancing the overall aesthetics of the plastered area.

Trowel

A trowel is a handheld tool with a flat, pointed blade used for spreading and smoothing plaster or other materials on surfaces, making it essential for achieving a uniform finish in plastering projects.

There are various types of trowels available, each designed for specific plastering techniques. The most common types include pointing trowels, margin trowels, and gauging trowels, each with their unique blade shapes and sizes.

- Pointing trowels are smaller and used for intricate work.

- Margin trowels are wider, making them preferable for mixing small amounts of materials.

- Gauging trowels have a rectangular blade, ideal for applying plaster and mortar in a controlled manner.

Depending on the project requirements, selecting the right trowel size and type is crucial for achieving a seamless and professional finish.

Plasterer's Hawk

A plasterer's hawk is a flat, square board with a handle underneath that allows plasterers to hold and transport plaster conveniently while working on walls or ceilings, providing a portable platform for easy access to the plaster.

Plasterers use the hawk to scoop up plaster from a larger bucket or tray, placing it on the board for quick application. The design of the hawk ensures that the plaster remains flat and accessible, preventing it from drying out too quickly. This tool enhances efficiency by eliminating the need to constantly return to the main source of plaster. The flat surface of the hawk enables precise spreading and smoothing of the plaster onto the surface being worked on, resulting in a more even and professional finish.

Plasterer's Darby

A plasterer's darby is a straight-edged tool used to level and straighten plaster or render surfaces, ensuring a smooth and even finish across walls or ceilings in plastering projects.

When applying plaster or render, it's crucial to achieve a flat and uniform surface for a professional result. This is where the plasterer's darby comes into play. By running the darby over the freshly applied material, excess material is scraped off, while simultaneously leveling the surface. This technique helps in removing imperfections, creating a seamless finish. The straight edge of the darby ensures that the surface is nice and level, ready for further finishing touches. Its use is essential for achieving that desired smoothness and consistency in plastering work.

Float

A float is a rectangular tool with a flat base and handle, used for smoothing and finishing plaster or stucco surfaces by pressing and leveling the material evenly, contributing to a polished and professional look in plastering applications.

Floats come in various sizes and shapes to cater to different needs and surface areas. A wooden float is commonly used for initial applications, while a steel float provides a smoother finish. Hawk is used to hold the plaster or stucco mix for easy access during application. Mastering the technique of floating is essential for achieving a seamless and flawless surface, avoiding uneven patches or rough textures in the final result.

Jointing Knife

A jointing knife is a flexible blade tool used for applying and smoothing joint compound or plaster along joints, corners, or edges, allowing for precise and clean finishes in plastering and drywall applications.

One of the primary functions of a jointing knife is to help achieve seamless joints and polished edges by spreading the compound evenly and smoothing it out for a professional-looking finish. The flexibility of the blade makes it easy to work with various angles and curves, ensuring that every joint is properly filled and leveled. This tool plays a crucial role in ensuring that the final surface is smooth and ready for painting or wallpapering, saving time and effort in the overall plastering process.

Plasterer's Brush

A plasterer's brush is a specialized tool with soft bristles used for smoothing and blending plaster or stucco surfaces, allowing for delicate and precise finishing touches in plastering projects.

When applying plaster or stucco to walls or ceilings, the plasterer's brush comes in handy by providing the perfect tool for achieving a seamless and uniform texture. The soft bristles enable a smooth application, ensuring that the surface is free from any unevenness or imperfections. This brush plays a crucial role in refining the plaster surface, allowing the plasterer to create unique and visually appealing textures that enhance the overall aesthetics of the space.

Bucket

A bucket is a versatile container used for mixing, carrying, and storing plaster, water, or other materials in plastering projects, providing a convenient and portable solution for preparing and transporting materials on-site.

For plastering tasks, having buckets on hand is essential for ensuring a smooth workflow. These unassuming containers play a crucial role in material management, allowing workers to neatly organize different components required for the job. Buckets contribute to the efficiency of the project by providing a designated space for mixing the plaster to the required consistency. With their sturdy handles and durable construction, buckets make it easier to move materials around the job site, minimizing disruptions and delays, and enabling a more streamlined plastering process.

Mixing Paddle

A mixing paddle is a specialized tool attached to a drill or mixer for blending plaster, mortar, or other construction materials quickly and efficiently, ensuring uniform consistency and smooth application in plastering projects.

When using a mixing paddle, the rotating motion created by the attached drill or mixer helps in breaking down lumps and evenly distributing the ingredients, resulting in a homogenous mixture. This process not only saves time by speeding up the blending process but also ensures that the materials are properly mixed for optimal performance on the project. Consistency in the mixture is crucial for achieving a professional finish, and reducing the risk of cracks, unevenness, or other application issues.

Plastering Machine

A plastering machine is a mechanical device that automates the process of applying plaster or render to surfaces, increasing efficiency and productivity in large-scale plastering projects by reducing manual labor and ensuring consistent results.

These machines are equipped with advanced technology, such as adjustable nozzle settings, which allow for precise application of plaster on various surfaces.

The use of plastering machines significantly speeds up the construction process, enabling builders to complete projects in a shorter timeframe while maintaining high-quality standards.

Plastering machines are versatile tools that can handle different types of plasters and finishes, offering flexibility in construction projects of varying complexities.

Plastering Level

A plastering level is a tool used to check and maintain the horizontal and vertical alignment of plastered surfaces, ensuring uniform thickness and smooth finishes in plastering applications, and aiding in achieving professional results.

These levels are essential in the construction industry, especially for projects that demand precision and high-quality finishes. By using a plastering level correctly, contractors can ensure that walls and ceilings are perfectly straight and level, without any bumps or imperfections.

- Plastering levels come in various types, including spirit levels, laser levels, and torpedo levels, each serving a specific purpose in the plastering process.

- They help in detecting any inconsistencies or deviations from the desired level, allowing for adjustments to be made promptly for a flawless finish.

- Properly leveled surfaces are crucial for the adherence of paint, wallpaper, or tiles, enhancing the overall aesthetic appeal of the space.

What Are The Optional Tools Used In Plastering?

Plus essential tools, optional tools like trowel sets, corner trowels, feather edges, rasps, and straightedges are used in plastering projects to enhance precision, detailing, and specialized finishes based on specific requirements.

One of the versatile optional tools used in plastering projects is the trowel set, which includes different types of trowels for various purposes such as smoothing, shaping, and spreading plaster efficiently. Corner trowels are specifically designed to create crisp, sharp corners with ease, ensuring clean and professional-looking edges. Feather edges help in feathering out plaster edges seamlessly, while rasps are handy for refining and shaping rough surfaces before the final finish. Straightedges play a crucial role in achieving flat and even surfaces by guiding the plaster application uniformly across the area.

Plastering Trowel Set

A plastering trowel set includes a variety of trowels with different shapes and sizes, offering versatility and precision in applying, shaping, and finishing plaster on surfaces in complex or detailed areas of a project.

These sets typically consist of pointed trowels for intricate detailing, margin trowels for tight corners, and gauging trowels for mixing and measuring the plaster mixture accurately. Additionally, trowel sets may include finishing trowels for achieving a smooth surface and plastering hawks for convenient plaster transportation. The specialized designs cater to specific needs in plastering work, like textured finishes or fine detailing on ornate surfaces.

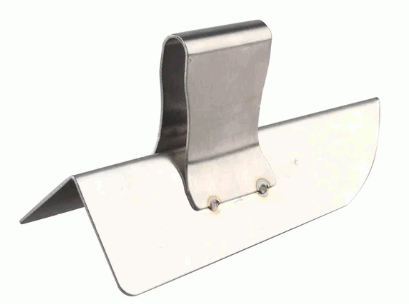

Plastering Corner Trowel

A plastering corner trowel is a specialized tool designed to facilitate the precise application and smoothing of plaster in tight corners, edges, or junctions, ensuring seamless and professional finishes in challenging areas of a project.

This tool plays a crucial role in achieving sharp angles and clean lines, ensuring that corners are perfectly formed without any plaster buildup. Plastering corner trowels are particularly useful when working on intricate work such as coving, and skirting, or when finishing off around window frames. They help in keeping the plaster level and consistent within corners, preventing any unevenness or rough edges.

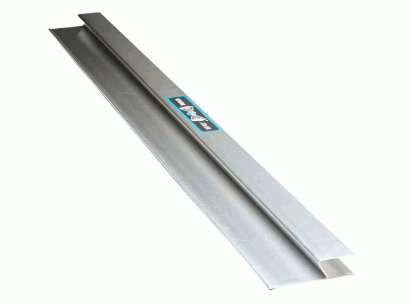

Plastering Feather Edge

A plastering feather edge is a thin, straight tool used for creating sharp and clean edges on plastered surfaces, allowing for precise shaping, leveling, and smoothing of edges in plastering applications.

It is an essential instrument in the toolkit of skilled plasterers, enabling them to achieve professional-quality finishes on walls and ceilings. When using a plastering feather edge, craftsmen can ensure that corners and edges are perfectly straight and uniform, giving a polished look to the overall surface. This tool is particularly handy for achieving crisp corners and defined edges, which are crucial for a visually appealing plastered surface.

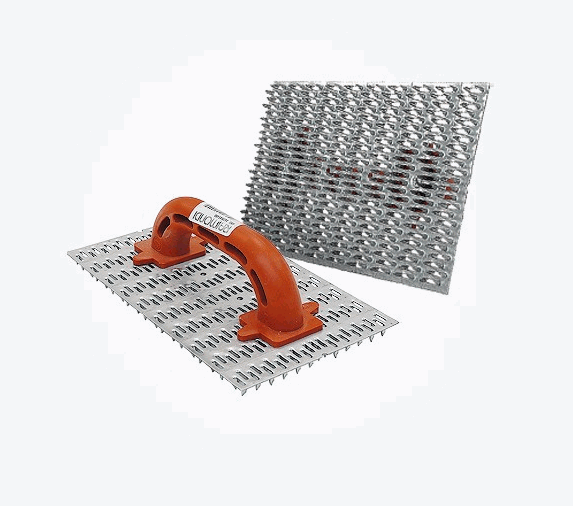

Plastering Rasp

A plastering rasp is a rough, abrasive tool used for shaping, sculpting, or texturing plaster surfaces by removing excess material, smoothing rough areas, or adding texture for decorative effects in plastering designs.

Plastering rasps are versatile instruments commonly utilized by skilled craftsmen to achieve intricate and customized plaster finishes. These rasps come in various shapes and sizes, offering a wide range of possibilities for creating unique textures and patterns. Using a plastering rasp allows artisans to unleash their creativity, transforming plain plaster surfaces into works of art with depth and visual interest. The precision and control provided by the rasp enable artisans to achieve smooth, seamless finishes or add interesting contours and details to their plaster creations.

Plastering Straightedge

A plastering straightedge is a long, flat tool used for checking and leveling plaster surfaces, ensuring uniform thickness, straight lines, and smooth finishes in large-scale plastering projects for consistent and professional results.

This essential tool is meticulously designed to provide accuracy and efficiency throughout the plastering process. By utilizing a plastering straightedge, craftsmen can verify the flatness of walls and ceilings, guaranteeing optimal adhesion of the plaster for a flawless application.

The straightedge aids in identifying imperfections and deviations in the surface, allowing for timely corrections to maintain the desired quality standards. Its versatility enables contractors to achieve a seamless transition between different sections, ensuring a cohesive and polished outcome.